135L/Min Plastic Diaphragm Pump High Pressure 8.3bar With Flap

Valves

Air diaphragm pump (also know as a Membrane pump, air operated double diaphragm pump(AOOD) or pneumatic diaphragm pump) that uses a combination of the reciprocating action of a

rubber,thermoplastic or diaphragm and suitable valves either side

of the diaphragm (check valve,butterfly valves,flap valves,or any

other form of shut-off valves) to pump a fluid.

| Item | Description | Unit | Reference Figure |

| 1 | Maximum air inlet pressure | Mpa | 0.83 |

| 2 | Maximum flow rate | 1/Min | 192 |

| 3 | Maximum lift | M | 70 |

| 4 | Maximum outlet pressure | Mpa | 0.83 |

| 5 | Maximum particle size | mm | 3 |

| 6 | Weight | kg | 12.3 |

| 7 | Noise level | db | <70 |

Applications:

Food industry: yogurt, whipped cream , ice cream , cheese blocks ,

whey , beer, malt , yeast , jam , syrup, soda , juice , pudding ,

tomato sauce , sesame paste, peanut butter , spices , cooking oil,

whey , etc.

Chemical industry : gels, facial cleanser, hand soap, shower gel,

washing powder , skin care products , hair dyes, refined sesame oil

, toothpaste, detergent , shampoo, shoe polish , cosmetics,

fragrances , soaps, balms , glycerin , fatty acids and so on.

Pharmaceutical industry: various types of pills paste, emulsifier,

syrup, nutrition , medicine , poultice , biological products, fish,

pollen, royal jelly , vaccines, health care and so on.

Chemical industry: fat, solvents, resins , polymers, paints,

pigments , dyes , paints, lubricants, grease , oil agent,

emulsified asphalt , adhesives, plastics , explosives, glass,

steel, leather and so on.

Construction industry : a variety of coatings, including interior

and exterior paint , corrosion materials, ceramic coatings, paints

, ceramic glazes and so on.

Other industries : plastics industry, textile industry, paper

industry , coal floating agent, nano-materials, bio- chemical

industry.

A 2 5 X X - X X X - X (model selection)

Form of pipe mouth:A-BSP B-NPT(F) C-Flange

Diaphragm material:9 – Santoprene H – Hytrel T - PTFE/Santoprene

Ball material:9 -Santoprene H – Hytre T – PTFE A - Acetal

Ball seat material:P/K –Polypropylene/Kynoar SS –Stainless Steel

Pump material: SS –Stainless Steel AL –Aluminum Alloy CI- Carbon

Steel P/K –Polypropylene/Kynoar

Maximum Applied Temperature Limits (diaphragm / ball / seal material)

Acetal ··············································· 40°- 150°F

(4.4- 65.5°C)

Santoprene········································· -40°- 225°F

(-40°- 107.2°C)

··················································40°- 220°F (4.4°-

104°C)

Nitrile···················································10°-

180°F (-12°- 82°C)

Viton····················································-40°-

350°F (-40°-176.6°C)

Hytrel····················································-20°-150°F

(-12°- 93°C)

Kynar····················································10°-200°F

(-28.9°- 65.5°C)

Polypropylene··········································32°- 175°F

(0-79.4°C)

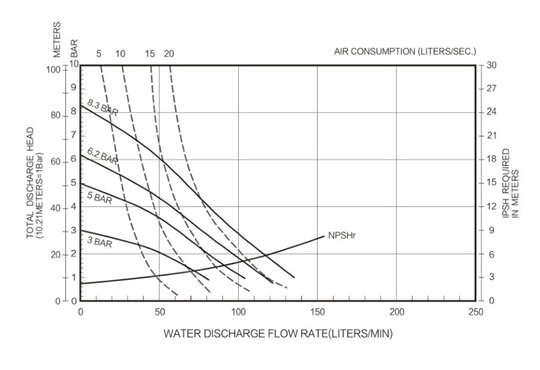

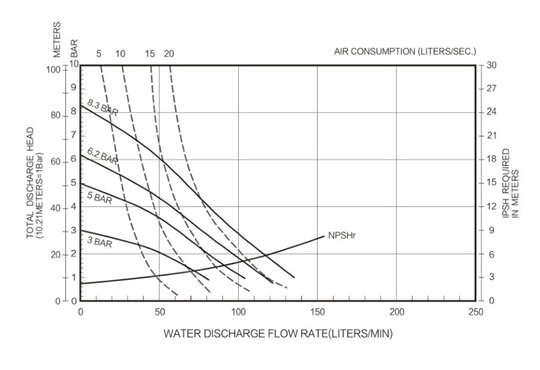

1” Flow diagram