Air Operated Double AODD Pump Low Air Pressure Non Leakage 70M Lift

AODD Pump Introduction

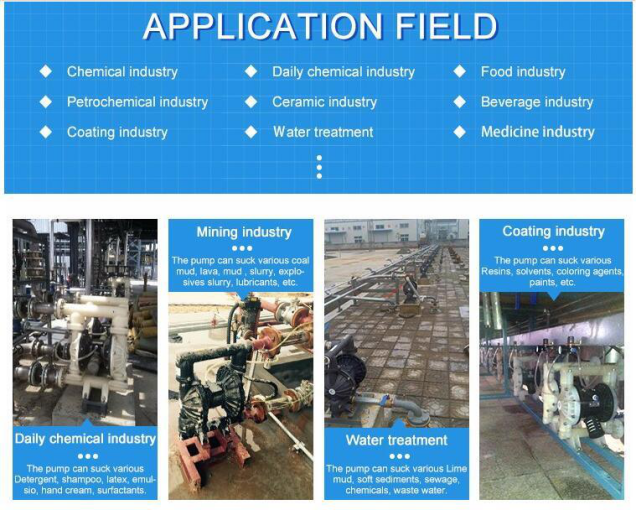

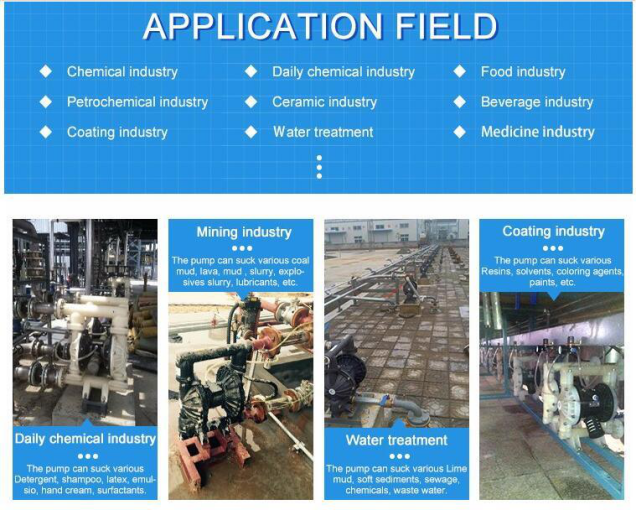

AODD Pump are machines for conveying or pressurizing fluids. The pump is

mainly used to transport water, oil, acid and alkali liquid,

emulsion, suspending emulsion and liquid metal, and also can

transport liquid, gas mixture and liquid containing suspended

solids. Pumps can generally be divided into three types according

to their working principles: volumetric pumps, power pumps and

other types of pumps. According to the driving method, it can be

divided into electric pump and water wheel pump, single-stage pump

and multi-stage pump according to the structure, boiler feed pump

and metering pump according to the use, and water pump, oil pump

and mud pump according to the nature of liquid delivery. According

to the shaft structure, it can be divided into linear pump and

traditional pump. Pumps can only transport fluid as the medium of

logistics, not solid.

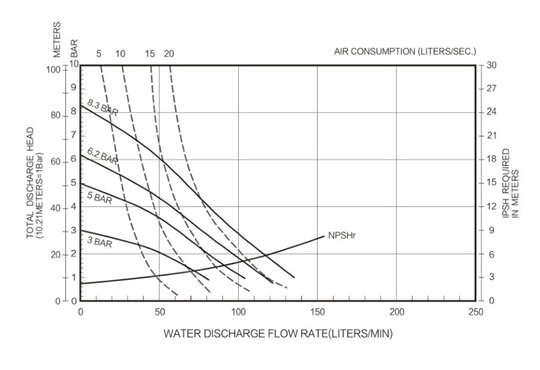

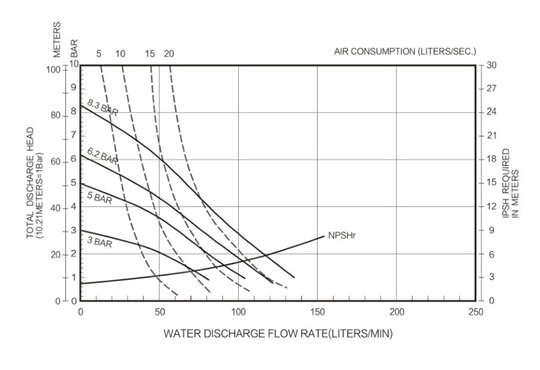

AODD Pump Parameters

| Item | Description | Unit | Reference Figure |

| 1 | Maximum air inlet pressure | Mpa | 0.83 |

| 2 | Maximum flow rate | L/Min | 192 |

| 3 | Maximum lift | M | 70 |

| 4 | Maximum outlet pressure | Mpa | 0.83 |

| 5 | Maximum particle size | mm | 3 |

| 6 | Weight | kg | 12.3 |

| 7 | Noise level | db | <70 |

diaphragm pump offers high volume delivery even at low air pressure

and a b road range of material compatibility options

available.Refer to the model and option chart.pump is provided with

the modularized air motor and fluid section.

The air operated diaphragm pump alternately generates the intake

fluid pressure and positive fluid pressure in the fluid chamber by

using the pressure difference in the air chamber. The ball valve

can ensure the forward flow of fluid.

Pump cycling will begin as air pressure is applied and it will

continue to pump and keep up with the demand. It will build and

maintain line pres -sure and will stop cycling once maximum line

pressure is reached (dis -pensing device closed) and will resume

pumping as needed.

AODD Pump Specifications

Air Diaphragm Pump

1. Non leakage

2. Good self priming performance

3. Convey all kinds of medium

4. Material:Cast steel,Alu,SS,PP

A 2 5 X X - X X X - X (model selection)

Form of pipe mouth:A-BSP B-NPT(F) C-Flange

Diaphragm material:9 – Santoprene H – Hytrel T - PTFE/Santoprene

Ball material:9 -Santoprene H – Hytre T – PTFE A - Acetal

Ball seat material:P/K –Polypropylene/Kynoar SS –Stainless Steel

Pump material: SS –Stainless Steel AL –Aluminum Alloy CI- Carbon

Steel P/K –Polypropylene/Kynoar

Maximum Applied Temperature Limits (diaphragm / ball / seal material)

Acetal ···············································40°- 150°F

(4.4- 65.5°C)

Santoprene·········································-40°- 225°F

(-40°- 107.2°C)

·················································40°- 220°F (4.4°-

104°C)

Nitrile··················································10°- 180°F

(-12°- 82°C)

Viton····················································-40°-

350°F (-40°-176.6°C)

Hytrel···················································-20°-150°F

(-12°- 93°C)

Kynar··················································10°-200°F

(-28.9°- 65.5°C)

Polypropylene··········································32°- 175°F

(0-79.4°C)

1” AODD Pump diagram